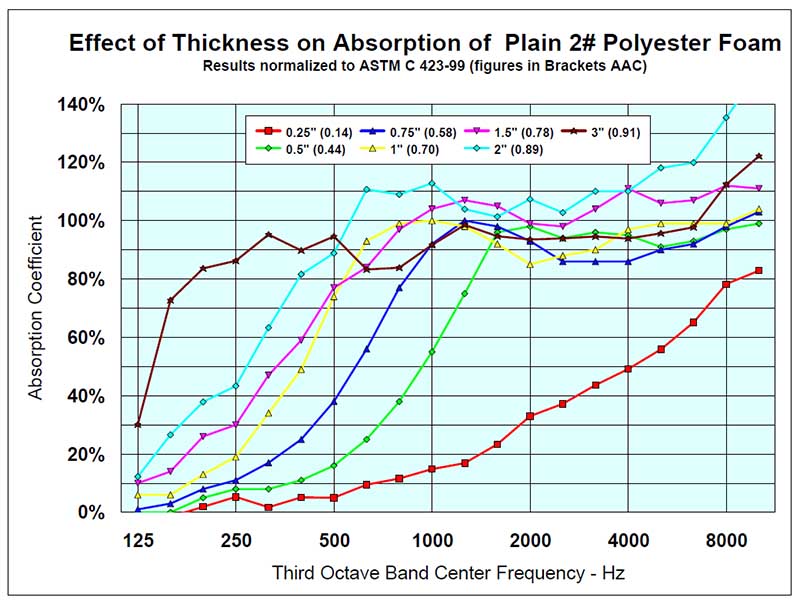

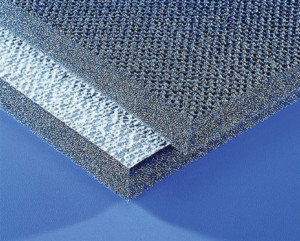

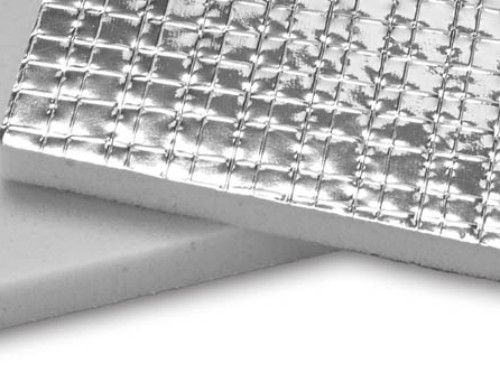

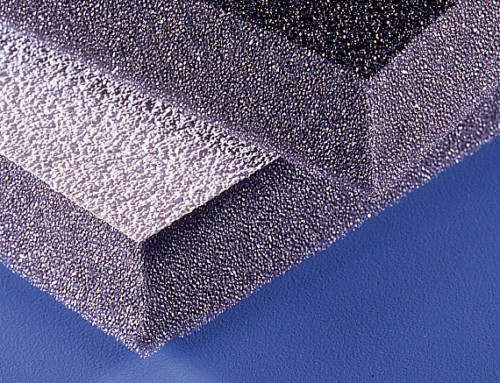

Embossed faced foam is a high performance acoustical material with superior absorption at the most critical frequency bands. It is often used in speaker housings, medical equipment, HVAC units, blower enclosures, and office equipment such as computer and printer housings. The embossed surface has an attractive, high tech appearance that is pleasant to the touch. It readily stands up to abusive air streams and the associated abrasion in air ducts and blower housings. Embossed foam increases sound absorption performance in the most critical frequency bands by 25% to 35% when compared to other available foams.

| Thickness |

Frequency (Hz) |

||||||

| 125 | 250 | 500 | 1K | 2K | 4K | NRC | |

| 1/2″ | .00 | .09 | .24 | .75 | .97 | .75 | .50 |

| 3/4″ | .07 | .13 | .29 | .82 | .86 | .89 | .55 |

| 1″ | .07 | .18 | .53 | .98 | .88 | 1.01 | .65 |

| 1-1/2″ | .08 | .31 | .71 | .94 | .97 | 1.05 | .75 |

| ASTM C423-90a Absorption Coefficient | |||||||

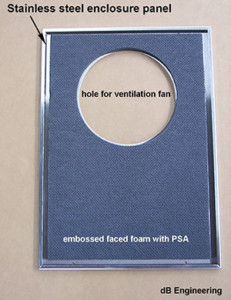

Embossed Foam in Use

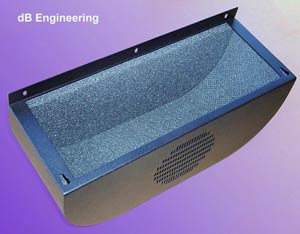

Embossed foam placed inside a speaker housing to correct reverberant noise.

Embossed foam placed inside a speaker housing to correct reverberant noise.

Embossed foam placed inside beverage dispenser knocks the noise down by five dBA.

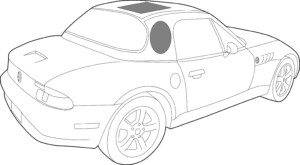

BMW Z3 roadsters with removable hardtop had drumming vibration noise at certain engine RPM. dB Engineering designed the composite kit that eliminated the offensive noise radiating inside the passenger compartment and subsequently went into their production.