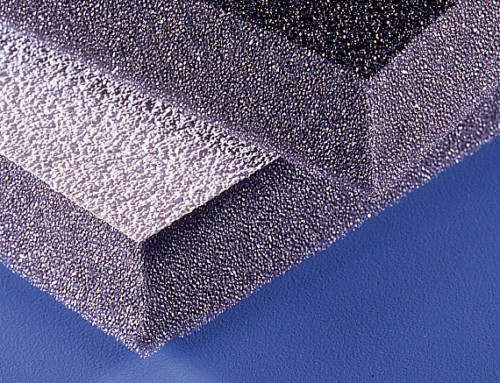

Foam Melamine is a lightweight, high temperature resistant, open cell foam manufactured from melamine resin. It combines excellent thermal properties with superior sound absorption capabilities to create a versatile fiber free product which can be applied in situations which may prohibit the use of urethane foams or fiberglass insulations.

This fire retardant foam meets the flame spread, smoke density and fuel contribution requirements necessary to comply with Class-1 building code regulations. The high performance thermal and acoustical characteristics of this flexible, low density foam make it an ideal product for in-plant and FDA approved applications. In addition to being the solution to aircraft and architectural noise problems, Melamine Foam is the material in use in OEM products requiring a combination of thermal and acoustical insulation capabilities. Optional facings can be applied for more durability and chemical resistance as well as pressure sensitive adhesive for ease of installation.

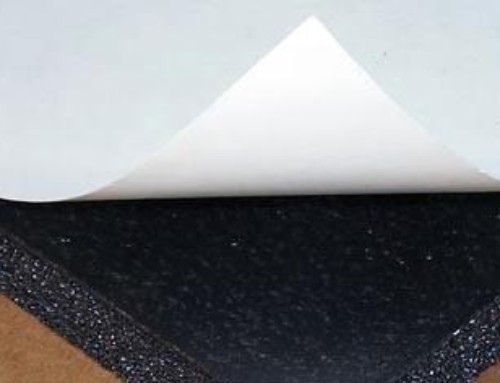

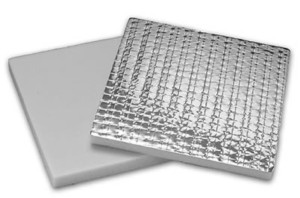

This is a reinforced Mylar faced melamine.

Physical Properties

Color: White

Density: .7 lb/ft3ASTM D3574-86 test A

Tear Strength: .5 ppi per ASTM D3574-86 test F

Tensile Strength: 18 psi per ASTM D3574-86 test E

Elongation: 15% per ASTM D3574-86 test E

| Flammability: | UL 94VO, UL-94 HF-1, UL 94-5, and FAR 25.853(a) |

| ASTM E84 Flame: 2.5; Smoke: 16.9 | |

| ASTM E162 Pass | |

| 662 Pass | |

| Boeing ATS 1000.001 Pass |

Thermal Conductivity: BTU/hr., Ft2., oF/in.; .25 per ASTM C 177

Temperature: -45o F – 302o F Continuous; to 400o F Intermittent

Standard Sizes:

Sheets: 24″ x 48″, 48″ x 48″, 48″ x 96″

Standard Thickness: 1/4″ to 18″

| Thickness |

Frequency (Hz) |

||||||

| 125 | 250 | 500 | 1K | 2K | 4K | NRC | |

| 1/2″ | .09 | .13 | .27 | .50 | .68 | .81 | .40 |

| 3/4″ | .09 | .15 | .39 | .65 | .80 | .90 | .50 |

| 1″ | .06 | .31 | .65 | .82 | .94 | .99 | .68 |

| 1-1/2″ | .19 | .35 | .75 | .98 | 1.01 | 1.03 | .75 |

| 1″ Reinforced Facing | .07 | .39 | 1.13 | .51 | .27 | .43 | .58 |

| ASTM C423-90a Absorption Coefficient | |||||||

|

Table showing how the human ear perceives noise reduction. |

|

| Decibel Reduction | Reduction Experienced by Ear |

| 2 | 15% |

| 4 | 23% |

| 6 | 38% |

| 8 | 48% |

| 10 | 56% |

| 12 | 63% |

| 14 | 68% |

| 16 | 75% |

| 18 | 77% |

| 20 | 81% |

Foam Melamine in Use

Example of how a blower muffler was cut and assembled to make a complete unit.

All our foam products do not drip upon ignition, cease to burn after removal of the source of ignition and produce a minimal amount of smoke.

IMPORTANT: When the foam is subjected to dirt, grease, moisture and chemical attack, it may require a foam with a protective surface treatment such as our Metalized Mylar or Matte Film Finish foams above.

Most of our products meet all the requirements of UL-94, MVSS-302 and FAR 25.83b. Call or e-mail to request expanded specifications and technical data sheets.