dB Engineering Noiseless Metal (NM) is laminated metal designed to reduce vibrations and noise transmission in metal constructions. It consists of two sheets of metal bonded together by a thin viscoelastic damping layer. NM can be made using any commercial quality steel or aluminum.

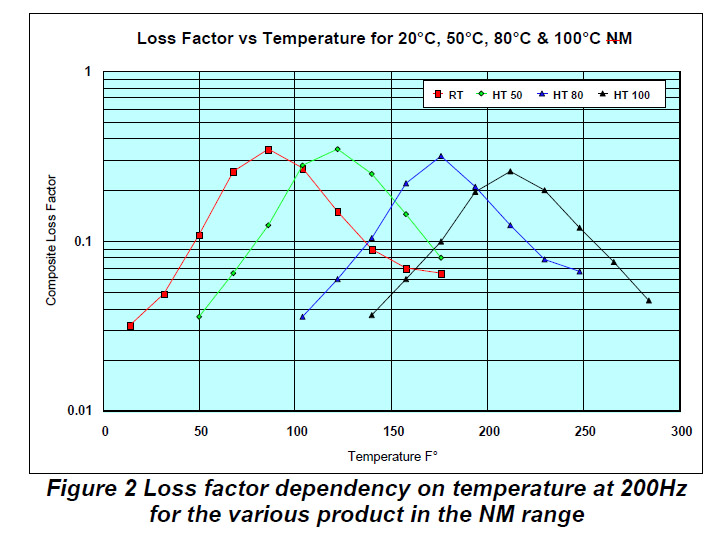

The structure-borne sound damping qualities of the viscoelastic core are temperature dependent. For this reason, NM panels are supplied with cores optimized for different temperature ranges, depending on the applications in which they are to be used. Standard products have viscoelastic cores optimized for room temperature, 50°C, 80°C and 100°C. In this way, it is possible to achieve maximum damping of structure-borne sound when they are built into various products such as internal combustion engines, washing machines, office machines and vehicle bodies.

The two metal facing sheets in NM panels are usually of Cold Rolled Galvanealed Steel, but in principle any type of metal or alloy can be used, as can other surface-treated sheets of various kinds. The metal facing sheets are usually of the same thickness, but a certain amount of asymmetry is permissible without any loss of acoustic properties

dB Engineering Noiseless Metal serves a dual function. It damps structure-borne sound, and it replaces the sheet that would otherwise be used in various applications, usually without it being necessary to accept an increase in the

thickness of the materials. dB Engineering Noiseless Metal can often eliminate the need for special screening or sound absorption, which would otherwise take up a considerable amount of space and increase the weight of a product.

Acoustic Properties

Damping of structure-borne sound

As a general rule, products constructed of thin metal sheet have very low internal loss. In other words, their ability to convert vibration energy into thermal energy is poor. This means that the resonant vibrations that may occur when they are subjected to vibration and structure-bound noise can be considerable, and will usually result in the radiation of a great deal of air-borne noise.

The internal losses in a material or structure are usually stated in terms of acoustic loss factor (η) by reference to the amount of vibration energy converted into heat, and thus not emitted as sound. A high loss factor reduces a structure’s level of vibration and consequently the amount of sound it emits. Where a material or structure is made up of several layers, the combined loss factor is stated as ηcomb.

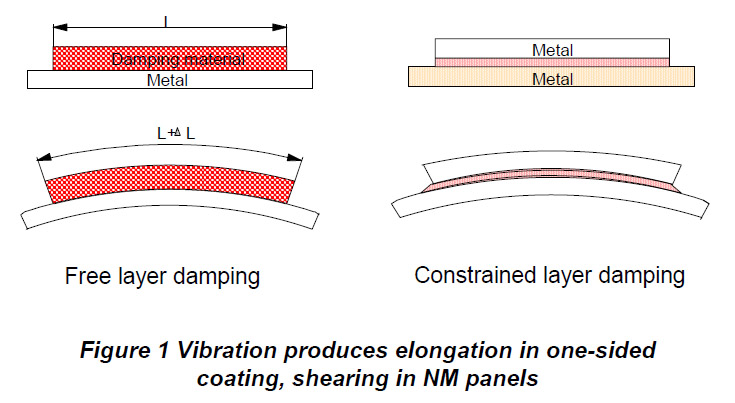

The highest realistically possible loss factor is approx 1. In the case of sheet metal structures it is usually between 0.001 and 0.01. Consequently, in structures of this type the internal loss is negligible, but it can be improved considerably if structure-borne sound damping materials are used. The most common methods involve coating one side of the sheet or using a sandwich construction. NM is an example of the latter method and, in optimum conditions, can achieve loss factor figures of around 0.4. These results are achieved using a sound damping core that is only 2 – 4mils (0.05-0.1 mm) thick.

Results as good as these are rarely obtained by coating one side of the sheet. This is because coatings are exposed to elongation/compression when subjected to bending waves, whereas the core of an NM panel is subjected to shear (see Fig 1). Shear converts larger amounts of energy than does elongation, resulting in higher energy losses and thus in a higher loss factor.

Unlike coatings, Noiseless Metal sandwich constructions make higher loss factors possible even with thick panels.

Temperature and Frequency

To a greater or lesser extent, the properties of all sound damping materials are dependent on temperature and frequency. Fig 2 illustrates loss factor dependency on temperature of the standard products in the Noiseless Metal range at 200 Hz.

Even though the loss factor is at its highest at the optimum temperature to which panels are subjected, good sound damping is achieved at temperatures both above and below the optimum. For example, the loss factor is higher than 0.05 over a temperature range of approx. 60° – 80°C. Loss factor is also dependent on frequency, but variations are insignificant between 100 Hz and 1000 Hz, which is the range usually of greatest interest.

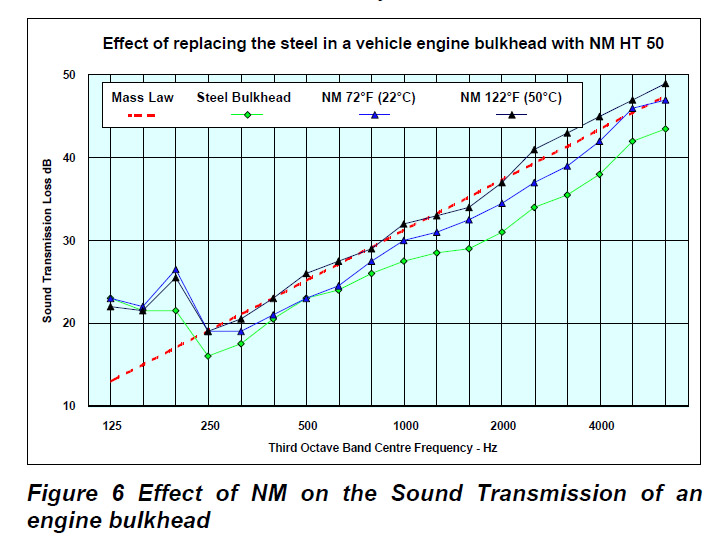

Insulation of Air-Borne Sound

In principle, dB Engineering Noiseless Metal panels follow the law of acoustic mass, which states that the reduction factor R increases by 6 dB for every doubling of the weight and by 6 dB for every doubling of the frequency. Thanks to the high loss factor, NM is practically free from resonance and coincidence problems that might otherwise detract from its airborne sound insulation properties. NM panels are therefore ideal for insulating airborne sound in both single-wall and double wall structures.

Areas of Application

Propulsion Systems

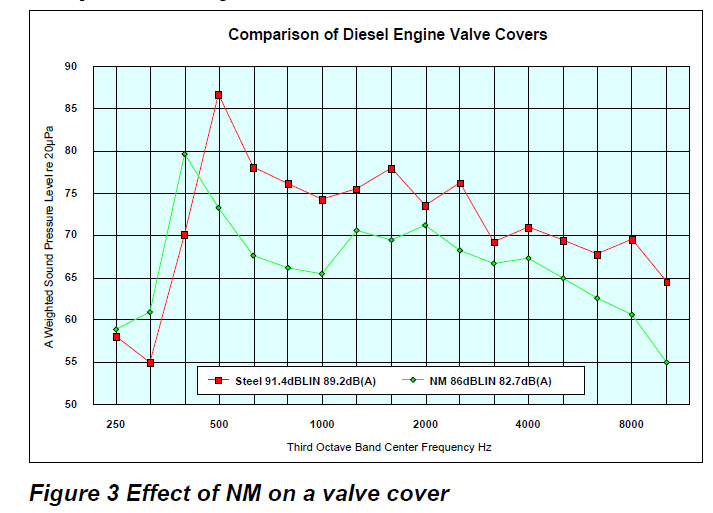

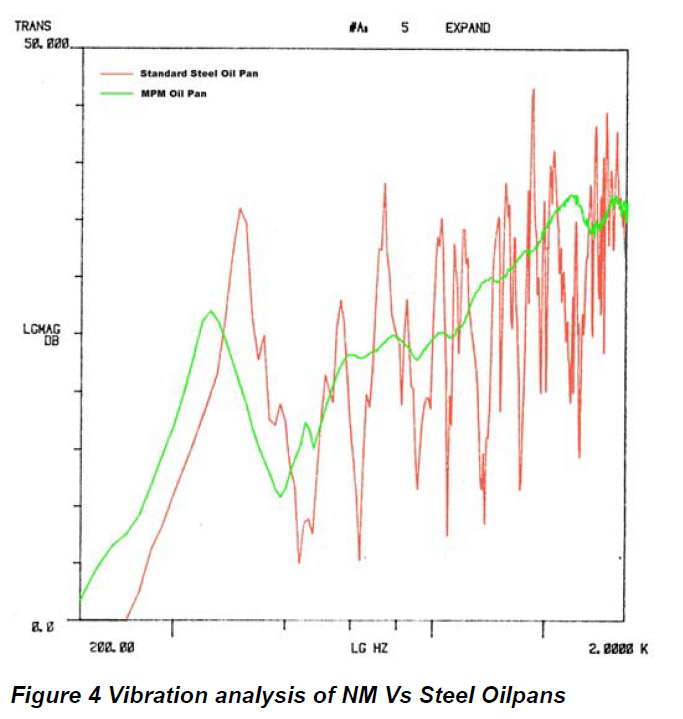

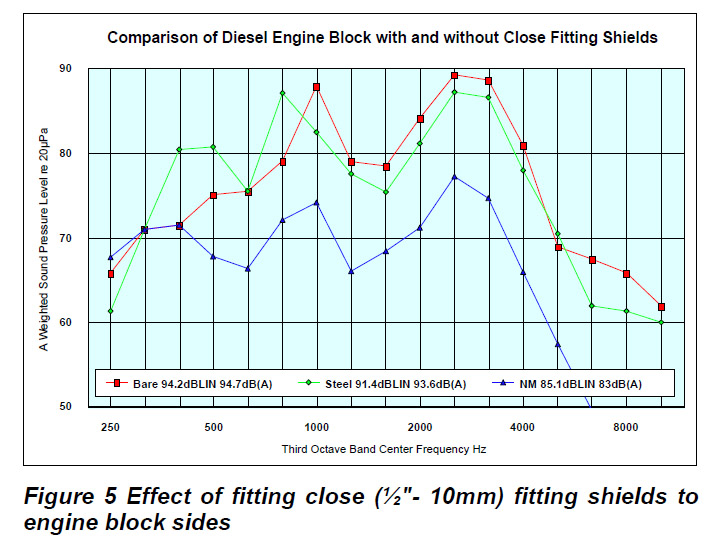

dB Engineering Noiseless Metal is a tried and tested material used in engines and gearboxes. It withstands heat and other strains and stresses to which a propulsion system is subjected. Scarcely any modifications in design are required when it is used to replace existing steel components, and as an original component, it has significant advantages over other alternatives such as plastic or aluminum.

NS panels are used as standard products in items such as

- Rocker covers, transmission covers and oil pans

- Engine shields and enclosures

- Ventilation ducts for air-cooled engines

- Gearbox cover covers and oil pans

Vehicle Bodies

Vehicle body components for trucks, vans and cars, pressed or drawn in dB Engineering Noiseless Metal, offer better damping and less transmission of noise from predominant source of noise it is possible to reduce the

volume of extra materials required and at the same time save space, weight, assembly time and money.

Other Vehicle Components

dB Engineering Noiseless Metal can also help to solve noise problems in many other vehicle components,

including:

- Air filters, especially those of the type that are permanently attached to the engine, thus giving rise to the risk of resonant vibrations with major noise radiation as a result

- Brake components, helping to reduce vibration and squealing from brake linings and discs

- Fastening brackets, helping to reduce vibration amplitude at critical resonances

Heavy Industrial Production

dB Engineering Noiseless Metal is used in the cowling walls of buses, in the floors of railway coaches and in the walls between sleeping compartments on overnight trains. In each of these cases, much of the noise derives from what is structure borne through the floor and wall paneling. The same applies to the driver’s cabs of tractors and construction site machinery.

NS also has many areas of application at sea, since the vibrations and structure-borne noise from a vessel’s engines, propellers and other sources of noise are spread through her hull, deck and bulkheads to areas where it can cause problems, such as the bridge and cabins.

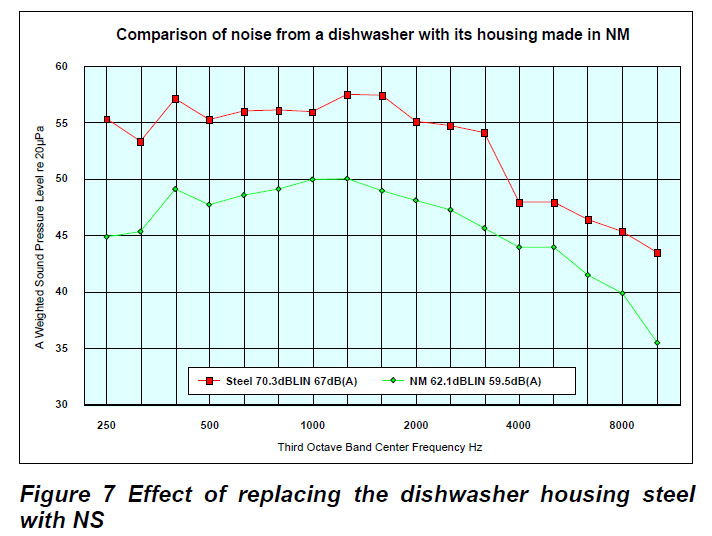

Office Machines And Domestic Appliances

dB Engineering Noiseless Metal is used in computers, printers and other office machines in which damping of structure-borne sound is essential. Even the quality of record players and loudspeaker units has been considerably improved by using NM panels in their construction. Where domestic appliances are concerned, the structure-borne sound damping properties of NM are used for damping the noise from dishwasher cabinets and other kitchen equipment.

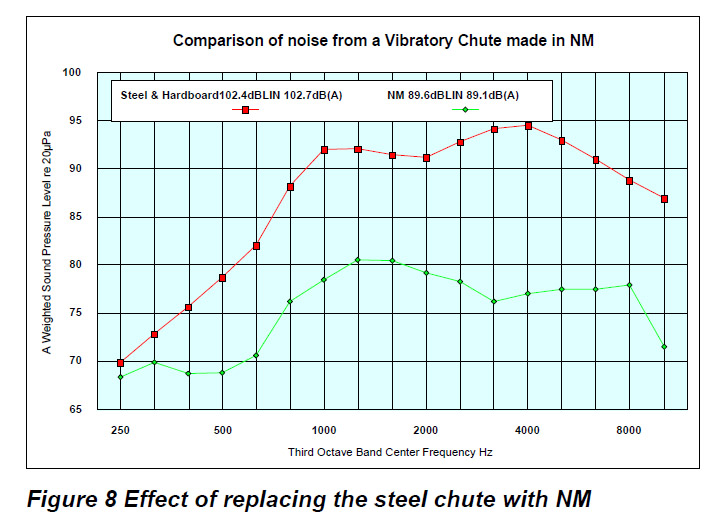

Factory Noise

In a factory, dB Engineering Noiseless Metal is used for machinery guards, vibrating feed units, conveyor belts, bottling machines, press hoods and rubbish containers. Manufacturers of plastic mills have found that NM offers the only effective means there is of reducing the noise of milling. And, as the laws relating to environment at work become more stringent, there will be even more areas of application for NM.

NM panels are also used in lifts, escalators, transformer boxes and relay cabinets, and in the floors and walls of gymnasiums and sports halls.

Working with Noiseless Metal

In many respects, Noiseless Metal can be worked and treated in the same ways as a homogeneous sheet. However, to ensure optimum results, it should be borne in mind that the core between the metal facing sheets is of softer material.

Pressing and deep drawing: NM panels can be stamped and pressed in the same tools as a homogeneous sheet. In certain cases, minor adjustments need to be made to tools and press settings.

Bending: Behavior is somewhat different from that of a homogeneous sheet, but operators can quickly learn how to bend NM panels with our advice.

Resistance welding of Noiseless Steel: Provided a current path is established between the two metal facing sheets, spot and seam welding can be carried out in the normal way without any major adjustments being necessary. In projection welding, the bridge between the two sheets must be adapted to the high current intensity. Butt welds can be used for fastening light parts.

Arc welding: Edge-welding using MIG or MAG techniques will usually present no problems, but special preparations should be made before welding at a distance from a free edge, and special techniques are required. To ensure that the core material does not affect weld strength as a result of incorrect procedures, we recommend special MIG and MAG training for all welding operatives.

Soldering and gas welding Noiseless Steel: Soldering is a suitable method, especially in the case of prototypes. Brazing should only be carried out very locally. Gas welding should be avoided.

Cutting: Clearance between cutting edges should be less than normal clearance when cutting a homogeneous sheet of the same total thickness. Cutting tools must be sharp.

Drilling: Holes with diameters of up to 4 mm can be drilled with ordinary drills. Larger holes should be drilled with stepped or cruciform drills.

Cleaning: NM panels can be cleaned in an alkaline bath, but should not be exposed to trichloroethane, white spirit or similar solvents over long periods.

Surface treatment: Every day many types of NM component are treated in spray, powder or electrical osmosis painting systems, free of problems. Temperatures in curing ovens should not be over 2300C during normal drying periods. Plating can be carried out following the usual procedures.

Screwed and riveted joints: The tension in screwed joints in certain NM components may occasionally reduce as the result of the core material being forced to one side, particularly at high temperatures. Various solutions are available if this phenomena occurs.

Gluing: Modern industrial glues can be used for permanently securing NM components, provided it is borne in mind that normally only one of the metal facing sheets will take the load on the panel.

Technical Data

| Metal: | commercial quality cold-rolled or electro-galvanized steel sheet, stainless steel or aluminum. |

| Thickness: | 0.045” (1.1 mm) to 0.130” (3.3 mm) with inner layer 2 – 4mils(0.05 – 0.1mm) |

| Adhesion: | 400 – 700psi (3 – 5 MPa) depending on type |

| Sizes: | 48” (1219mm) by 96” (2438mm) or 120” (3048mm) |

| Storage: | Temperature range 32°F to 86°F (0°C to 30°C) Maximum of 50 panels per stack. Store horizontally Max 12 months |

| Handling: | NM should be worked after stabilizing at room temperature |