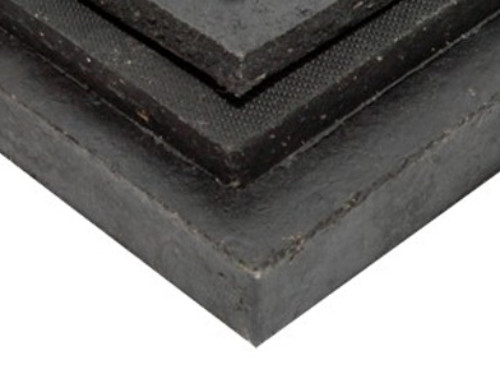

dBmat is a noise control material specifically designed to achieve maximum attenuation over a broad frequency range. dBmat combines dense, limp, flexible, non-lead loaded barriers with dBcloth foams providing a total noise control system. Unlike other composites available, these multilayer systems are manufactured without costly adhesives, thus eliminating the potential for failure between layers.

Designed by acoustical engineers, dBmat has been optimized to economically provide:

- High Transmission Loss – The barrier’s ability to impede airborne noise.

- High Noise Reduction Coefficients – The foam’s ability to absorb airborne sound energy with minimum reflection.

- Damping – The composite’s ability to attenuate structure-borne vibration on metals and plastics thereby reducing reradiate noise and material fatigue.

The diversity of constructions makes possible engineered solutions for most OEM and in-plant applications. dBmat is available with single and double layer septums, various barrier weights, foam thicknesses and a variety of surface treatments. dBmat is available in rolls, sheets, die cut or fabricated to customer specifications or can be easily cut with a knife or scissors. These composites can be adhered to the substrate with factory supplied, economical, SBR pressure sensitive adhesive or an acrylic based pressure sensitive adhesive for temperatures up to 250o F. It is recommended that a contact adhesive or mechanical fasteners be used for these heavily loaded composites in overhead applications.

Many OEM customers have dB Engineering cut their acoustical material into parts so that assembly can be made easily at their facility. These parts can be shipped by the part number as seen in this photo, or sent as a predetermined “kit.” These “kits” consist of several different parts that are grouped together to go to one particular product on the assembly line.

Physical Properties:

Typical of Most Composites

- Color Barrier – Black; Foam – Charcoal Gray

- Density Barrier – 1.5 to 2 lb./ft2.; Foam – 2lb./ft.3

- Tear Strength 20 lbs in min. ASTM D624, DIE C

- Tensile Strength 240 lbs sq. in. min. ASTM D 412, DIE 1

- Peel Strength 2.2 lbs in. min., ASTM D903

- Elongation 120%

- Flammability MVSS 302, SAE J369, Special Formulation to UL-94V and FAR 25.853

- Temperature Range -30 degrees Fahrenheit to +200 degrees Fahrenheit

MIL-STD-810 at 250 degrees Fahrenheit, 7 24 hr. periods PASS - Cold Crack MIL-STD-810 at -25 degrees Fahrenheit, 1″ mandral PASS

- Thermal Conductivity .30-.38 BTU in per hr. sq. ft. degrees Fahrenheit ASTM C518

Acoustical Properties:

Sound Transmission Loss, dB (ASTM-E90-75)

| Barrier Weight | Frequency (Hz) | ||||||

| lb/ft2 | 125 | 250 | 500 | 1K | 2K | 4K | STC |

| .5 | 10 | 12 | 16 | 21 | 26 | 32 | 20 |

| .75 | 12 | 16 | 20 | 25 | 28 | 34 | 23 |

| 1 | 15 | 17 | 21 | 27 | 32 | 36 | 26 |

| 1.5 | 14 | 19 | 25 | 36 | 33 | 37 | 30 |

dBmat non-reinforced barrier septum is a flexible vinyl used by itself or in combination with absorptive material as an additive mass treatment for existing equipment enclosures or housings, and as a pipe or duct wrap. dBmat reinforced vinyl is used in conjunction with grommets and Velcro to provide a suspended enclosure for in-plant applications. It is available with quilted or encapsulated fiberglass for added absorption and to meet Class A flammability requirements.

dBMat in Use

Foam barrier composite attached by insulation anchors to inside of enclosure.

Acoustical foam is the most versatile of all noise control materials. dB Engineering has the right foam for your application.