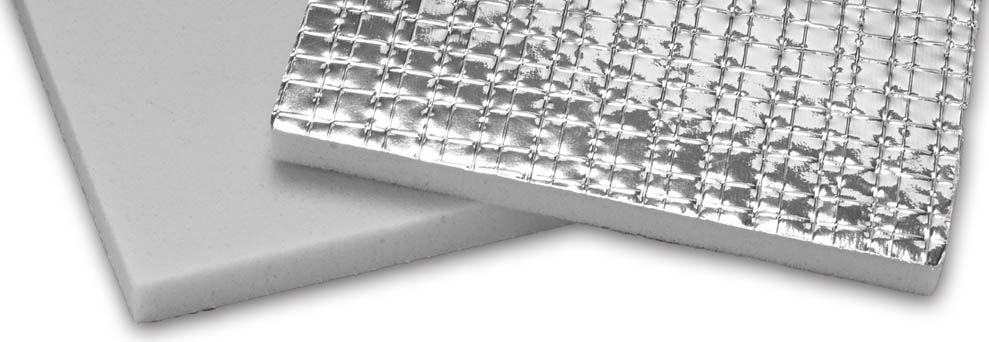

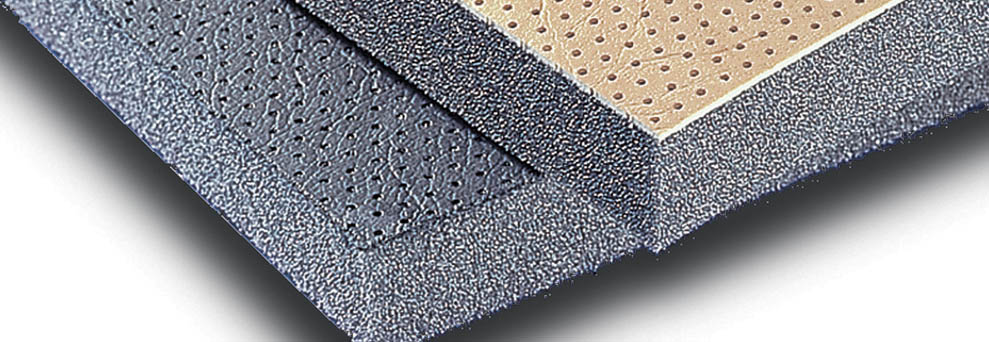

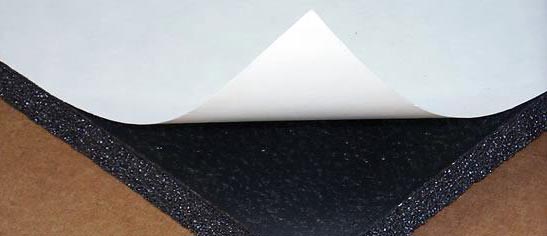

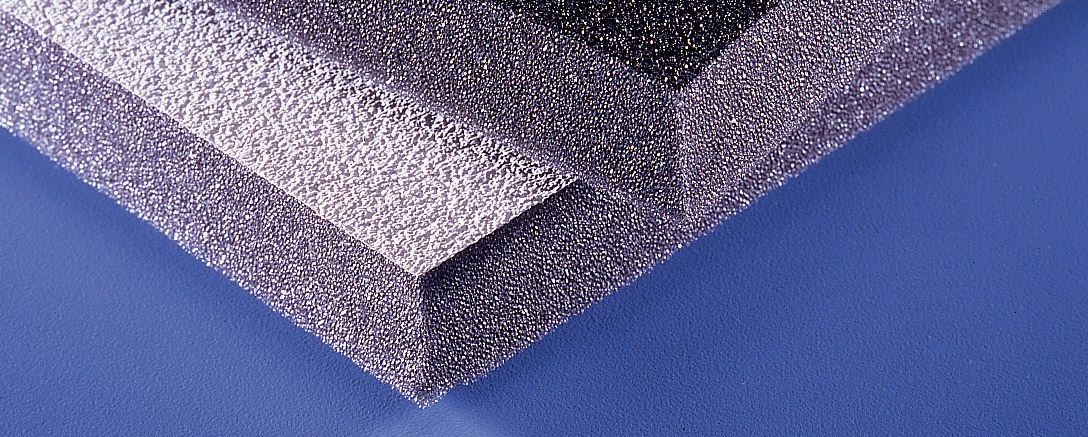

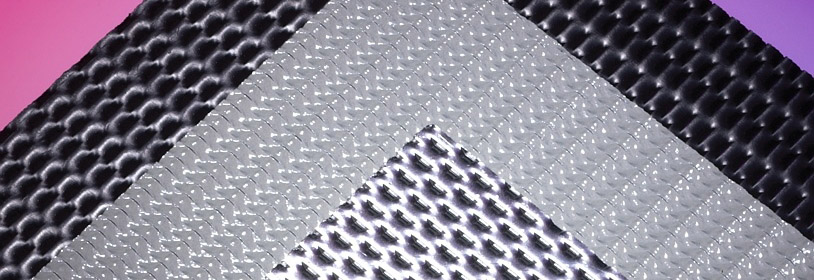

dBcloth acoustical foams are designed to provide maximum absorption of airborne sound with minimum thickness and weight. These flexible polyurethane open cell foam products are manufactured to optimize pore size, air flow resistance, and density.

Sound energy, passing through the cell structure, is converted into minute quantities of low grade heat that is easily dissipated. Since the uniformity of the cells are carefully controlled the efficiency is constant and predictable from one installation to another.