Sound Absorption plus Vibration Damping

The need to absorb noise inside a machine enclosure often accompanies the need to damp vibration on the same structure. Where it is not possible to totally enclose a noise source, as in many types of machinery, electrical appliances, office equipment and electronic controls, the inside of the enclosure should be lined with sound absorption material. This provides a non-reflective surface that absorbs air noise generated by gears, linkages, fan blades and rotors. To reduce vibration noise generated by the same enclosure, particularly if it is of sheet metal, damping is necessary.

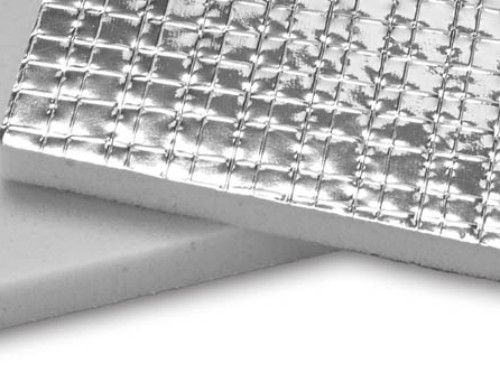

Adhesive release paper, .050 inch thick damping, embossed foam, composite shown upside down for viewing purposes.

Embossed Foam Damping Sheet consists of a thickness of embossed foam bonded to a thin sheet of high-efficiency damping compound. In this configuration, Embossed Foam Damping Sheet has proved to be a most satisfactory single solution to this twofold problem.

Available with or without high-quality, pressure-sensitive adhesive backing, it is easy to apply and has a neat appearance.

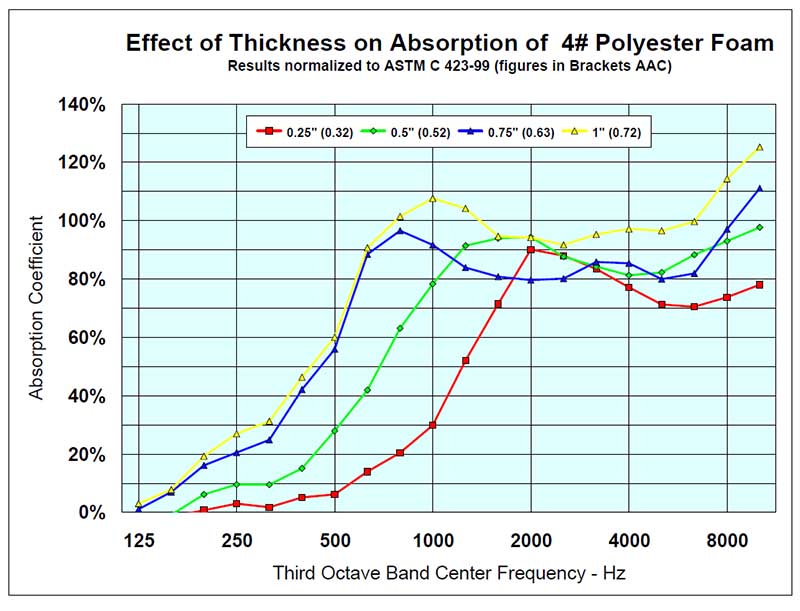

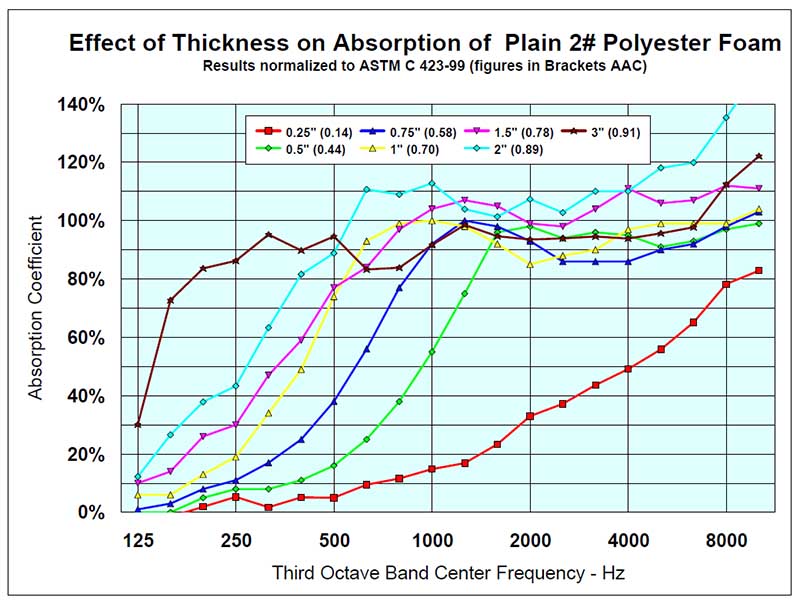

All thicknesses – 1/4″, 1/2″, 3/4″, and 1″ are effective for absorbing high-noise frequencies. When lower frequencies are dominant, however, thicker foams and fewer openings in the enclosure are required. Absorption values and damping rates are shown below.

BMW Z3 roadsters with removable hardtop had drumming vibration noise at certain engine RPM. dB Engineering designed the composite kit that eliminated the offensive noise radiating inside the passenger compartment and subsequently went into their production.

Foam damping sheet placed inside air conditioning unit for heavy equipment cab.

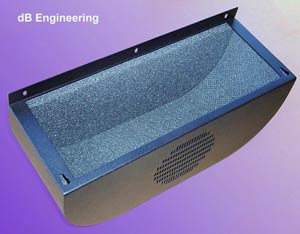

An OEM blower manufacturer using plain faced acoustical foam to quiet a blower cabinet.

Table 1

|

Absorption Coefficient % for Embossed Foam Damping Sheet |

|||||

|

Foam Thickness |

Frequency – Hz |

||||

| 250 | 500 | 1000 | 2000 | 4000 | |

| 1/4″ | 10 | 16 | 24 | 45 | 93 |

| 1/2″ | 15 | 26 | 58 | 90 | 98 |

| 3/4″ | 28 | 58 | 88 | 94 | 92 |

| 1″ | 30 | 65 | 92 | 90 | 84 |

Table 2

| Amount of Damping at 70o F | ||||

| Steel Thickness (Gauge) | 16 | 18 | 20 | 22 |

| % of Critical Damping | 7.50 | 9.00 | 12.50 | 17.50 |

| Loss Factor | .15 | .18 | .25 | .35 |

| Magnification Ratio Q | 7 | 5 | 4 | 3 |

| Specifications: | |

| Foam Thickness | 1/4″, 1/2″, 3/4″, 1″ Standard |

| Sheet Size | 24″ x 54″ and 54″ x 75″ |

| Damping Layer | 0.050″ |

| Damping Weight | 0.33#/sq.ft. |

| Foam Density | 2 lbs./ft.3 |

| Sound Absorption | See Table 1 |

| Damping Value | See Table 2 |

| Color | Charcoal |

| Effective Temp. Range | +32o to 175o F |

| Min. & Max. Temp. Range | -45o to 225o F continuous 250o F. intermittent |

| Decay Rate Geiger Plate | 75dB/sec. @ 72o F. |

| Resistance: | |

| Water | Fair |

| Petroleum | Good |

| Alkalis | Good |

| Fungus | ASTM-1924-63 |

| Thermal “K” | 0.25 BTU/in./hr./sq.ft./ oF |

| Flame* | Foam: UL 94 HF-1 FAR 25.853 Part B. Damping Sheet: UL 94 V-0 Composite: UL 94 HBF |

| Aging | No Changes in 10 Years |

| Pressure Sensitive Adhesive Peel Strength | 6 Lbs./in., 180o Peel |

| ASTM-D-903-49 | @ 12″/min. |

| *This numerical flame spread rating is not intended to reflect hazards presented by this or any other material under actual fire conditions. The Federal Trade Commission considers that there are no existing test methods or standards regarding flammability that are accurate indicators of the performance of cellular plastic materials under actual fire conditions. Any results of existing test methods, such as ASTM D-1692 and UL 94, are intended only as measurements of the performance of such materials under specific, controlled conditions. | |

How to Apply

Damping surface must be clean, free of dirt, oil or grease. It can be applied to a clean painted surface. Sometimes, on very smooth surfaces etching or roughing the surface may be required. Sheet is cut to size with knife, shears or steel rule die. If sheet is adhesive backed, strip away the protective paper, use roller to apply adhesive side to surface.

The surface treated need not be covered 100% to achieve high damping effectiveness. A 2/3 area coverage provides at least 80% of the total damping expected.